“New laser technology has allowed us to innovate by engraving a ‘cleaner’ cell with thinner cell walls,” said Sean Tobler, Business Development Manager at Harris & Bruno. “This is a natural progression from coarse, highly structured cells to a more fine cell built for better release of fluid and solids. This design has improved the flow of coating out of the cells to the coating blanket, which helps transfer solids in particulate coatings exceptionally well. The open nature of the cell, combined with its interrupted structure, means that it can minimize foaming while limiting slinging for less viscous, water-based coatings,” he added.

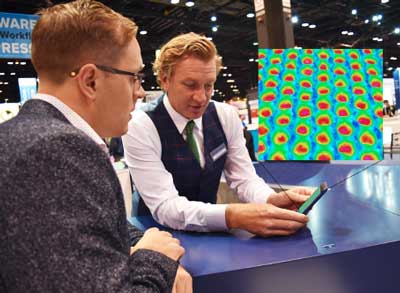

The new Quantum Roller will positively affect Koenig & Bauer’s customers in many ways. With the advancement of laser engraving, Harris & Bruno had the opportunity to research different engravings, smoother cells and thinner walls. Koenig & Bauer was seeking an engraving to lay down smooth and consistent coatings that will work with the Harris & Bruno chamber in all of Koenig & Bauer’s presses, and across all sizes.

“When initially discussing with Harris & Bruno the need for such an engraving, they took on-board the requests and came back with Quantum Open Cell technology,” said Chris Travis, Director of Technology at Koenig & Bauer. “This takes it to new levels and can benefit all printers with the majority of coatings out there today. This is a low-cost method to add bite to current coating effects when using Soft Touch and matte. We have seen the benefits just by changing the roller. Customers using UV gloss coatings will see a smoother laydown. It will be especially appealing to our high-volume packaging customers for pure consumption savings. Specialized folding carton converters will also see a more pronounced effect with their current coatings. Plus, it has been designed with an engraving angle and direction that allow for more coating release in relation to the chamber, and from the anilox to the coating plate,” Travis added.