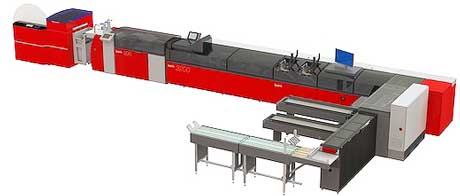

Kern (Konolfingen, Switzerland) has launched its new 3200 Inserter – a high-performance, multi-format inserting system that introduces automatic switching between different envelope sizes for the first time, to achieve faster changeover times between applications and class-leading uninterrupted processing. The new machine will come in three versions to cater for all speed requirements up to 24,000 envelopes per hour. The company’s first new high-speed inserter launched since 2016, the Kern 3200 can be used wherever there is demand for flexible and complex requirements that must handle both transactional and direct mail. The multi-format machine has a newly developed inserting module at its core, which can be equipped with more than one envelope magazine. This unique concept in this class of inserter means that different jobs can be run in succession, without an operator having to intervene and change envelopes. Also announced was a faster version of Kern’s existing 1600 inserter machine, able to handle speeds of up to 16,000 envelopes an hour. Along with the three new 3200s, the expanded entry-level 1600 range completes Kern’s inserter platform of six inserters, designed to cater to all industry requirements as many customers shift to shorter runs and demand more flexibility.

Kern’s 3200 is the only system in its performance class that can be equipped with more than one envelope feeder, said the OEM. This means that automatic envelope changeovers between C4, C5 and DL envelopes while running multiple jobs can be done. The system’s three different models can offer speeds of up to 24,000 envelopes per hour, while the Kern 1600 can offers either 8,000, 12,000 or 16,000 envelopes per hour. Offering a wide range of possible applications, the 3200 Inserter can be combined and equipped with a wide variety of modules. These include multi-channel solutions for special applications, multiple inputs in different performance classes, single-sheet inputs and various feeders for feeding inserts. The system can also be equipped with up to 16 insertion stations (friction or rotary feeders) while at it exit, it can be supplemented with a Print@Exit digital printing system.

tablet for allergy on skin <a href="[Link deleted]medication primary name prescription only allergy medication

buy generic prednisone 20mg <a href="[Link deleted]prednisone 40mg pill

ibuprofen for stomach ache <a href="[Link deleted]20mg brand

strongest acne over the counter <a href="[Link deleted]prednisone acne treatments that work uk

best nausea medicine in hospitals <a href="[Link deleted]order

isotretinoin pills <a href="[Link deleted]absorica generic how to buy isotretinoin

amoxicillin pills <a href="[Link deleted]amoxil 500mg pills amoxil buy online

doctor sleep online free <a href="[Link deleted]generic melatonin 3 mg

purchase azithromycin without prescription <a href="[Link deleted]azithromycin generic azithromycin pills

gabapentin 600mg cost <a href="[Link deleted]100mg sale

azipro 250mg cheap <a href="[Link deleted]250mg over the counter order azithromycin 250mg generic

buy generic furosemide diuretic <a href="[Link deleted]furosemide 100mg pills

buy omnacortil 40mg for sale <a href="[Link deleted]prednisolone pill omnacortil over the counter

buy generic amoxicillin 1000mg <a href="[Link deleted]generic cheap amoxil generic

buy doxycycline generic <a href="[Link deleted]generic doxycycline 200mg

albuterol 2mg pill <a href="[Link deleted]pill buy generic albuterol online

buy generic augmentin over the counter <a href="[Link deleted]augmentin 1000mg online

order levoxyl generic <a href="[Link deleted]levoxyl without prescription buy levothyroxine sale

levitra 10mg cheap <a href="[Link deleted]over the counter

buy clomiphene 50mg pills <a href="[Link deleted]medication order serophene generic

zanaflex tablet <a href="[Link deleted]zanaflex tablets buy zanaflex pills

prednisone order <a href="[Link deleted]prednisone 20mg pills buy prednisone 5mg online cheap

order ventolin inhalator generic <a href="[Link deleted]albuterol for sale asthma pills over the counter

buy augmentin <a href="[Link deleted]without prescription generic augmentin 625mg

cheap omnacortil 5mg <a href="[Link deleted]drug prednisolone 20mg drug

purchase clomid pills <a href="[Link deleted]without prescription purchase clomiphene generic

buy neurontin <a href="[Link deleted]800mg for sale cheap neurontin 600mg

viagra overnight shipping usa <a href="[Link deleted]order order viagra 50mg online cheap

order furosemide 40mg sale <a href="[Link deleted]pills order furosemide 100mg pills

rybelsus pills <a href="[Link deleted]semaglutide 14mg online semaglutide cost

doxycycline ca <a href="[Link deleted]monodox online cheap order monodox sale

real casinos online no deposit <a href="[Link deleted]casinos for usa players blackjack card game

levitra us <a href="[Link deleted]uk order levitra 10mg pills

pregabalin 75mg cost <a href="[Link deleted]lyrica tablets order pregabalin pills

hydroxychloroquine us <a href="[Link deleted]online buy buy generic hydroxychloroquine 200mg

triamcinolone 4mg brand <a href="[Link deleted]10mg pill order aristocort online

tadalafil 40mg generic <a href="[Link deleted]generic tadalafil brand cialis pills

order cenforce 50mg sale <a href="[Link deleted]100mg without prescription buy cenforce 100mg pill

buy generic loratadine <a href="[Link deleted]loratadine 10mg for sale claritin 10mg drug

generic aralen 250mg <a href="[Link deleted]generic aralen online buy aralen 250mg generic

order dapoxetine 90mg pills <a href="[Link deleted]60mg pills purchase cytotec for sale

glycomet medication <a href="[Link deleted]generic metformin 500mg buy generic glycomet

generic glycomet <a href="[Link deleted]order purchase glycomet online cheap

brand lipitor 40mg <a href="[Link deleted]10mg over the counter buy atorvastatin 40mg pill

buy norvasc tablets <a href="[Link deleted]10mg without prescription buy norvasc 10mg for sale

acyclovir 400mg brand <a href="[Link deleted]zyloprim 300mg pills allopurinol 100mg us

lisinopril 5mg for sale buy lisinopril 10mg generic order zestril sale

where can i buy crestor <a href="[Link deleted]zetia online purchase zetia online cheap

omeprazole over the counter <a href="[Link deleted]canada omeprazole 10mg price

buy domperidone 10mg pill <a href="[Link deleted]motilium 10mg pill buy generic sumycin 250mg

order metoprolol <a href="[Link deleted]lopressor 50mg pills metoprolol 50mg for sale

buy cyclobenzaprine <a href="[Link deleted]to buy ozobax purchase baclofen pills

toradol 10mg sale <a href="[Link deleted]to get gloperba without a prescription colchicine 0.5mg pills

thesis writers <a href="[Link deleted]can i buy a research paper cheap thesis binding

buy generic inderal over the counter <a href="[Link deleted]clopidogrel 75mg sale buy plavix 75mg generic

buy methotrexate generic <a href="[Link deleted]5mg pill coumadin 2mg tablet

buy mobic generic <a href="[Link deleted]meloxicam online buy celecoxib no prescription